Design Methods of Infrared Optical Lens

time2021/06/08

- The design of the infrared optical lens determines its quality and performance and has a great influence on the work effectively in the application process. This article will specifically introduce the design method of infrared optical lens.

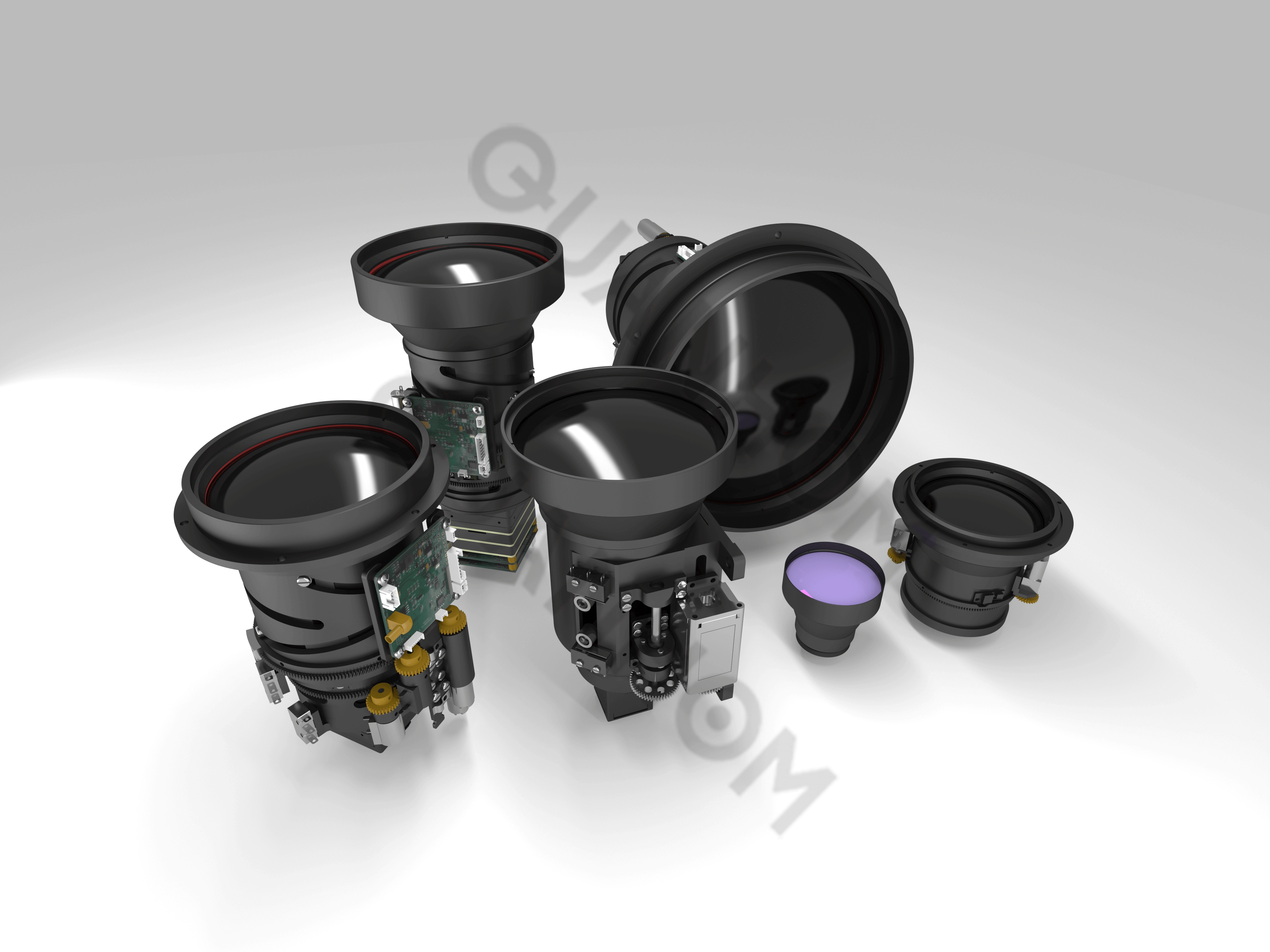

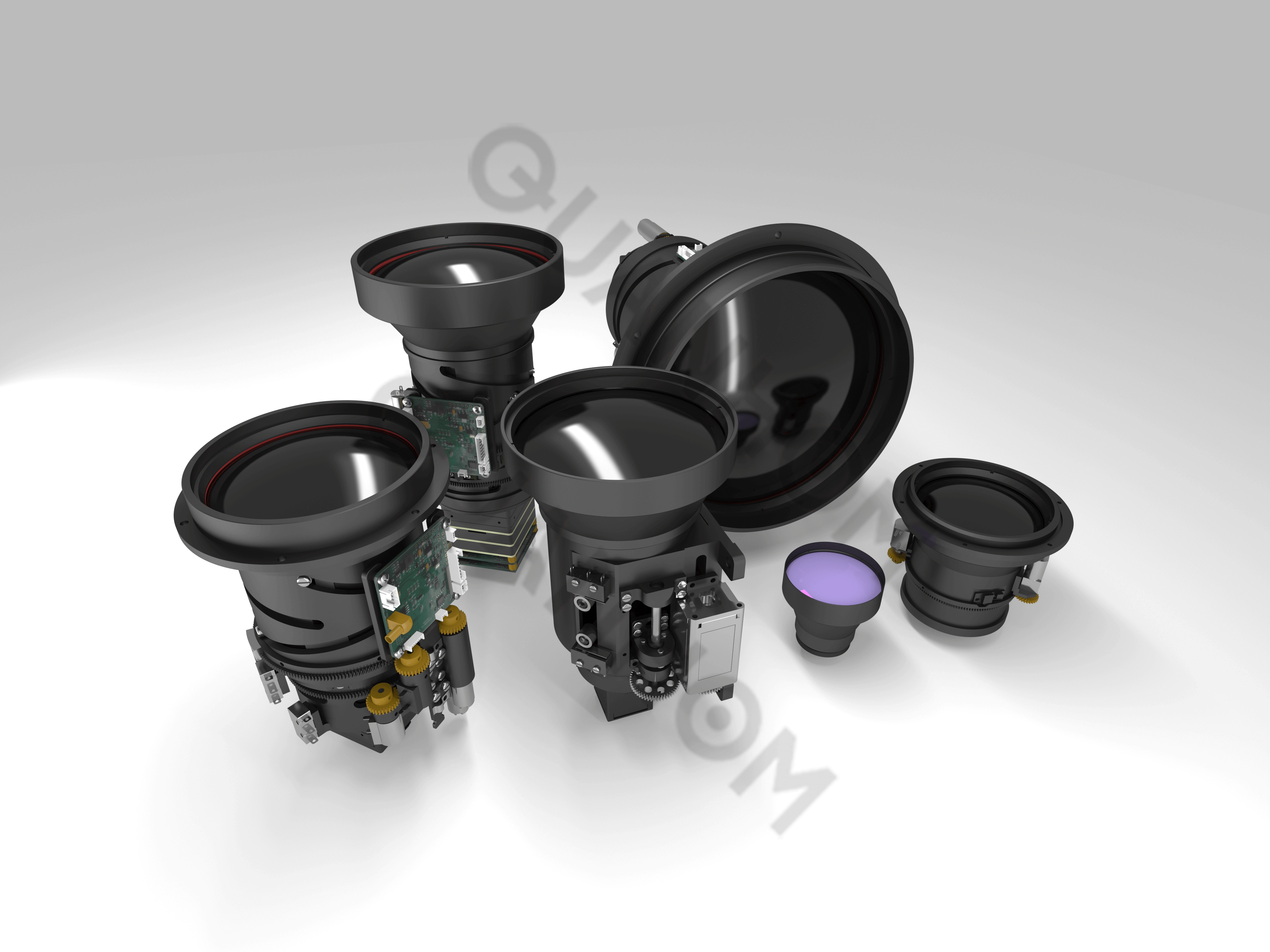

Infrared imaging is to converge the detected optical signal to the detector through a lens group, and then the detector and its backtrack convert the optical signal to the electrical signal. The detector and the application field are different, the lens material used in the optical system is also different. According to the characteristics of different infrared lens materials, processing methods and process equipment are also different. The following are the design methods of different infrared optical lenses.

SWIR lens

SWIR lenses, especially SWIR short-wave infrared lenses with extended wavebands, can use materials that need to consider factors such as wide-band transmission, processing, and visible light transmission. Therefore, ZNSE, ZNS, CaF2, etc. have become common choices. In addition, there are some rare ones. Glass. However, it should be noted that under normal circumstances, these glasses are not in stock and the production frequency is not high. Therefore, before adopting, it is necessary to determine whether these materials can be delivered on time and have the possibility of continuous supply.

MWIR lens

The MWIR lens is usually used with a medium-wave refrigerated detector. The diaphragm is placed behind the lens, so the lens is relatively large, and the so-called cold-light-bar effect (ghosting, reflection, also called cold-screen effect) must be considered. Although the cooling lens and the detector are large in size, the detection distance can reach a long distance, such as the focal length of 150 mm, 300 mm, and the distance of 10 km to 30 km can be seen.

LWIR lens

The design of the LWIR lens is commercialized, which is to be both cheap and effective. Therefore, aspherical surfaces are more commonly used. In addition, with the popularization of commercial applications, such as in-vehicle night vision, rifle sights, mobile phones, etc., chalcogenide glass has become a hot topic for such applications. Since it can be molded at a low temperature, the price of a chalcogenide glass lens can be very low (if the quantity is large).

In extremely cold and extremely hot conditions, especially when the temperature difference is large, the curvature of the infrared lens, the thickness of the lens, the refractive index of the lens barrel, and the lens material will cause the lens to defocus. In order to ensure clear imaging, the lens needs to be refocused. Electric or manual focusing is required. In order to eliminate the adverse effects of temperature changes, an athermal design is required. Usually, designers will use different optical materials for optical compensation (temperature difference) or use mechanical materials and optical materials. In the opposite design, optical-mechanical compensation is performed. There is also an AF auto-focusing design, which uses software technology to continuously approach the focal plane, thereby electric focusing and auto-focusing.

Dual field of view, three fields of view design

The dual field of view and three fields of view design refer to a set of lenses that can be fixed and different focal lengths at different positions, such as 25 mm, 50 mm, and 75 mm. The optical design of this type of lens only needs to consider the imaging quality at the three focal points and does not need to consider the image quality changes during the change process. This is a very practical design. For example, it is easy to find the target in the case of a small focal length of 25 mm. You can quickly switch to a focal length of 50 mm or 75 mm to zoom in and see the target clearly.

Infrared continuous zoom lens

Continuous zoom lens (continuous zoom) can be regarded as the most challenging lens, and the higher the zoom ratio, the higher the difficulty. In addition to the high optical challenges, the mechanical structure is also extremely difficult. This is very difficult for the design requirements, and of course, its performance is far beyond expectations.

Reflective design

Reflective designs generally appear on lenses with long focal lengths. This is to reduce the size of the lens (too long), and a reflective lens is added to the optical path to fold back to shorten the length. Due to the wide infrared band, the general metal film can achieve the effect of reflection.

Temperature measurement, an imaging lens

The design of the temperature measuring lens and the design of the imaging lens has some different considerations. Due to the need for temperature measurement, the focus of lens design is to reduce reflections or stray light, etc., and properly handle the position and size of the diaphragm. Its relative contrast uniformity is one of the most important indicators for evaluating the quality of a lens. A good lens design requires comprehensive consideration of the effects of optical and mechanical coordination, and neither is indispensable. There is also good optomechanical simulation software on the market, specifically to improve the effect of optomechanical coordination.

The design of the infrared optical lens needs to be designed according to the pixel and size of the detector, specific application occasions, and cost-effective factors. If you want to know more information related to the infrared optical lens after reading the above content, you can get a comprehensive solution by contacting us!

As a professional manufacturer of Opto-electromechanical components, we have accumulated rich experience in designing and manufacturing a wide range of thermal infrared lenses (infrared lenses including LWIR, MWIR, and SWIR). We have a strong R&D team and professional production department, which can provide you with excellent quality products. At the same time, we are also committed to providing customers with thoughtful one-stop service and effective solutions. If you are interested in our infrared optical lens, please contact us immediately!