The Design Features of Super Field of View Infrared Optical Lenses

time2021/10/22

- In order to achieve good performance of the super field of view infrared optical lens, we need to consider multiple aspects in the design. This article will specifically introduce the design features of superfield of view infrared optical lenses.

The super field of view infrared optical lens is mainly used in the military to warn and indicate incoming missiles or infrared threat targets. It can be deployed on weapon equipment platforms (such as airborne, vehicle-mounted, and ship-borne platforms) at the same time to realize the panorama It can view 360°alarm and possess Omni-directional situational awareness. It is an important military optoelectronic product.

Ultra-large field of view infrared optical lens has some characteristics of wide-angle lens and infrared optical lens, but at the same time, it is different from the ordinary infrared optical lens, specifically in the following aspects.

(1) There is a large negative distortion

When the field of view of the optical system exceeds 60°, when the ideal imaging mode is adopted, the image height will increase sharply with the increase of the field of view. For a detector with limited image size, a large amount of negative distortion must be introduced to obtain enough field of view.

(2) Has a large negative vignetting

The illuminance of the image plane of the system is proportional to the fourth power of the cosine of the incident light angle.

Because of the relatively large field of view of the optical system. For example, when Half the field of view angle is 65°, the edge illuminance is only about 40% of the center illuminance. Therefore, in the optical design, a large negative vignetting must be introduced to the edge field of view to increase the luminous flux and improve illuminance.

(3) Non-thermal design requirements

Like other military infrared optical lenses, it needs to meet the military's wide temperature range (usually a typical temperature range is -55 ~ 70 ℃) of excellent imaging quality.

(4) The important factors of image quality evaluation are different

When used to warn the incoming missile, compared with the conventional infrared optical lens, the infrared optical lens with a super field of view mainly focuses on the indication accuracy and range of the target. This is reflected in the uniformity of single-pixel angular resolution and single-pixel energy convergence.

In recent years, many scholars at home and abroad have conducted research on the super field of view infrared optical lenses, and the research content is mainly concentrated on the part of optical lenses.

Among them, the detector area used in the optical lens is small; there are many optical elements; the length of the lens is longer; the optical and mechanical structural parts are realized by titanium alloy with small thermal expansion coefficient, but high density, low thermal conductivity, and poor workability; it has no heat The technical means of athermal design is realized by refraction diffraction.

In this article, starting from the application requirements, the design characteristics of the superfield of view infrared optical lens are analyzed.

The detector used in the optical system is a 1 024×1 024@15 μm large area array mediumwave refrigerated infrared detector, which uses only 4 lenses and does not contain a diffractive surface to realize an optical passive athermal design. The material of the optomechanical structure is aluminum alloy, the lens structure is compact, the total length is less than 69 mm, and the optical field of view reaches 116°.

In combination with actual engineering application requirements, the design features of the superfield of view infrared optical lens are analyzed in terms of projection mode, optical configuration, image surface illuminance, the field of view, thermalization, and evaluation mode.

Projection method

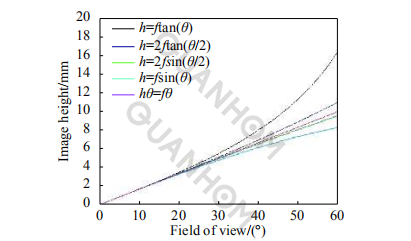

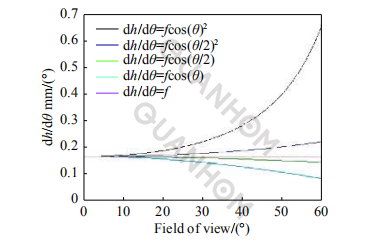

For imaging of objects at infinity, an ideal optical lens with an imaging distortion of 0 has an image height and field of view in accordance with the following formula, namely:

h = f tanθ (1)

Where: f is the focal length of the object side; θ is the half-field angle of the object side.

It can be seen from formula (1) that when the half-field angle is large, the image height will increase sharply. Therefore, the super-large field-of-view optical lens must introduce a certain amount of negative distortion can design a sufficient imaging field of view on limited image size.

The design of the super field of view lens adopts the "non-similar" imaging principle, and the object area that the ideal optical lens cannot imagine is deformed and compressed by introducing negative distortion to the image. The imaging image height and field of view usually conform to the following projection methods:

h = 2 f tan(θ/2) (2)

h = 2 f sin(θ/2) (3)

h = f sinθ (4)

h = f θ (5)

Taking the derivation on both sides of formulas (2)~(5) respectively, the relationship between angular resolution and field of view is obtained as follows:

dh/dθ = f / cos (θ/2)2 (6)

dh/dθ = f cos(θ/2) (7)

dh/dθ = f cos(θ) (8)

dh/dθ = f (9)

The relationship between image height and field of view corresponding to different projection methods is shown in Figure 1(a), and the relationship between angular resolution and field angle corresponding to different projection methods is shown in Figure 1(b).

In the actual use of the super field of view infrared optical lens, the infrared target is usually a point target after being imaged by the optical system. Compared with the geometric feature information of the target, the system is more concerned about its angular position information in order to obtain higher angular position indication accuracy.

It can be seen from the figure that the h = f θ projection method, the image height is proportional to the field of view, the single-pixel angular resolution does not change with the field of view, and the overall field of view is consistent. Therefore, the military super field of view infrared optical lens should choose the h = f θ projection method.

(a) Relation between image height and field of view angle

(b) Relationship between angular resolution and field of view

Fig.1 Relationship between the image height and angular resolution with the angle of view under different projection modes.

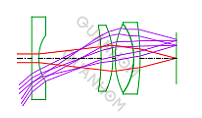

Optical configuration

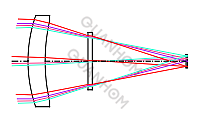

The super field of view infrared optical lens has the characteristics of a reversal telephoto lens, in which the front lens group has negative refractive power and the rear lens group has positive refractive power, as shown in Figure 2(a).

(a) Inversed telephoto

(b) Cold stop

Fig.2 Optical configuration

This power distribution has two advantages:

(1) The off-axis field of view has a certain negative vignetting, which can make the cross-sectional area of the oblique beam much larger than the cross-sectional area of the axial light beam. Uniformity of overall illuminance is better.

(2) It has a long lens length, which is conducive to structural design and installation.

In addition, military infrared optical systems generally use cooled detectors, which have higher sensitivity than uncooled detectors. The cooled detector has a diaphragm (also called the cold diaphragm) at the front end of the detector. To avoid stray radiation, it is necessary to ensure that the exit pupil of the optical system must match the detector cold diaphragm (which is generally called 100% cold aperture efficiency), as shown in Figure 2(b).

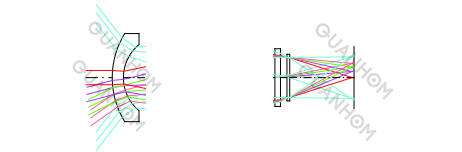

Image surface illuminance

The angle of incidence of the incident light from the edge field of view and the central field of view of the super field of view infrared optical lens is quite different, as shown in Figure 3(a); The incident angles of the beams in the field and the central field of view are also quite different, as shown in Figure 3(b), both of which will lead to uneven illumination on the image surface.

(a)Input optical path (b) Detector receiving optical path

Fig.3 Influencing factors of image illumination

Athermalized method

At present, there are three commonly used athermal design methods, mechanical passive, electronic active, and optical passive. The super field of view infrared optical lens is more suitable for the realization of passive athermalization. The analysis is as follows:

(1) Since combat platforms usually have strict restrictions on the weight and volume of optical lenses, lightweight materials should be considered as much as possible for structural parts, so mechanical passives are generally not considered.

(2) Electronic active athermalization technology, focusing by moving the lens or lens group, will cause the focal length of the optical system to change during the focusing process, and then the field of view will change accordingly, and ultimately affect the accuracy of the alarm.

(3) Optical passive athermalization technology refers to the use of different thermal and chromatic aberration characteristics between optical materials and the thermal expansion characteristics of structural materials, through the reasonable distribution of optical power, element spacing, and selection of structural materials, so that the system is in the required temperature range Inside, its thermal defocus is approximately zero.

Although it is difficult to realize optical passive athermalization technology, the athermalization effect is good and the reliability is high.

Field of view analysis

For infrared optical lenses with a large field of view, a reasonable design of the field of view can significantly reduce the difficulty of optical design, which has an important impact on improving the imaging quality and simplifying the structure of the optical system.

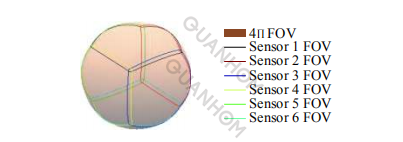

Weapon equipment platforms generally have to deploy multiple super-large field-of-view infrared optical lenses to monitor the 360° airspace in real-time. In order to avoid blind spots in the field of view splicing and reduce the overlap rate of the field of view, the field of view of a single optical system must be reasonably selected.

Figure 4 shows a field of view layout, in which the field of view area to be covered by a single optical lens is 94°×94°, the overlapping rate of the field of view between adjacent lenses is 4°, and the 4π spherical space is combined by 6 optical lenses to achieve full coverage.

Fig.4 Field layout of optical lens

Evaluation method

Like ordinary military infrared optical systems, the evaluation methods of super-large field-of-view infrared optical systems should include optical transfer function (MTF), dot pattern (RMS), high and low-temperature performance (athermal design), etc. In addition, there are special requirements for the angular resolution and energy concentration of the optical system.

(1) Angular resolution

In the actual use of the super field of view infrared optical system, the infrared target is usually a point target after being imaged by the optical system. Compared with the geometric characteristic information of the target, the system is more concerned about its angular position information in order to obtain higher warning indication accuracy. The performance evaluation method in the design is reflected in the distortion of the system and the uniformity of angular resolution in the entire field of view.

(2) Energy concentration

The general situation of optical design is that the performance of the on-axis field of view is usually better than that of the edge field of view, which can be well reflected in the MTF.

For example, a mid-wave infrared lens has an F-number of 2, a focal length of 50 mm, and a Field of 6°, at 33 lp/mm, the measured field of view on the MTF axis is 0.6, and the fringe field of view is 0.4, which means that at this spatial frequency (usually the characteristic frequency determined by the pixel size of the detector). The full field of view is the resolution of the geometric features of the target is better, and the resolution of the on-axis field of view to the target is better than that of the edge field of view.

As for the super field of view infrared optical system, in actual use, the targets are mostly pointed targets (or small area targets) after being imaged by the optical system. The resolution of the details of the target's geometric features is not important, and the system is more concerned. It is the distance at which the target can be detected.

Usually, the detection distance of the target in the edge field of view and the on-axis field of view is not allowed to have a large difference. This is reflected in the evaluation method of the optical design is the energy concentration of a single pixel, and the optical design must take into account the consistency of the energy concentration of the on-axis and edge fields of view.

In this article, combined with actual engineering applications, the design features of the super field of view infrared optical system are analyzed in terms of projection mode, optical configuration, image surface illuminance, the field of view analysis, athermalization, evaluation method, etc. so that everyone can better understand the characteristics and advantages of the super field of view infrared optical lens. If you want to know more about infrared optical lenses after reading the above, Quanhom is happy to provide you with professional suggestions and solutions.

As a professional manufacturer of thermal infrared lenses (including LWIR, MWIR, and SWIR), we have won praise and trust from many customers with our excellent technology and high-quality products. We have a professional production team and a range of quality control. At the same time, we can also provide thoughtful one-stop service according to customer needs. If you are interested in our LWIR lens, please contact us immediately!

References:

[1] Zhang Yuansheng. Development of airborne electro-optical warning system [J]. Electronics Optics & Control, 2015, 22(6): 52−55. (in Chinese)

[2] Huang Fuyu, Shen Xueju, He Yongqiang, et al. Performance analysis of the super-wide field of view imaging system used for space target detection [J]. Infrared and Laser Engineering, 2015, 44(10): 3134−3140. (in Chinese)

[3] Yang Shengjie. Optical design for high resolution cooled mid wavelength infrared wide-angle imaging system [J]. Acta Optica Sinica, 2012, 32(8): 0822003. (in Chinese)

[4] Hirsh I, Shkedy L, Chen D, et al. Hybrid dual-color MWIR detector for airborne missile warning systems[C]// Proceedings of SPIE,2012, 12: 83530H1-12.

[5] Tao Zhi, Wang Min, Xiao Weijun, et al. Design for cooled dual-band infrared refractive-diffractive hybrid optical system of athermalization and wide FOV [J]. Acta Photonica Sinica, 2017, 46(11): 1122004. (in Chinese)

[6] Oskotsky. Wide angle MWIR F-Theta lens:Russia, 236344A1[P].2018.

[7] Chen Chen, Hu Chunhai, Li Weishan, et al. Calculation method of relative illumination of lens image plane [J]. Acta Optica Sinica, 2016, 36(11): 1108001. (in Chinese)

[8] Zhong Xing, Zhang Yuan, Jin Guang. Illumination uniformity optimization of wide-viewing-field optical system [J]. Acta Optica Sinica